Jit Hinchman, CSCP, Engineering & Supply Chain Professional

Dr. Stephen G. Timme, President, FinListics Solutions

Supply chain collaboration is defined as companies working together to achieve competitive advantage in the market. Supply chain collaboration delivers business benefits including higher customer and supplier satisfaction, better visibility, improved agility, and lower operating risk. These business benefits help companies achieve financial benefits such as higher revenue growth, increased profitability, and asset utilization. Supply chain collaboration can be applied widely; it depends on where and what part your business plays in the supply chain network. It’s important for organizations to know where to collaborate to combine strengths. They should effectively communicate with common understanding and clear goals. Furthermore, business relationships need to be based on trust to successfully implement and execute supply chain collaboration.

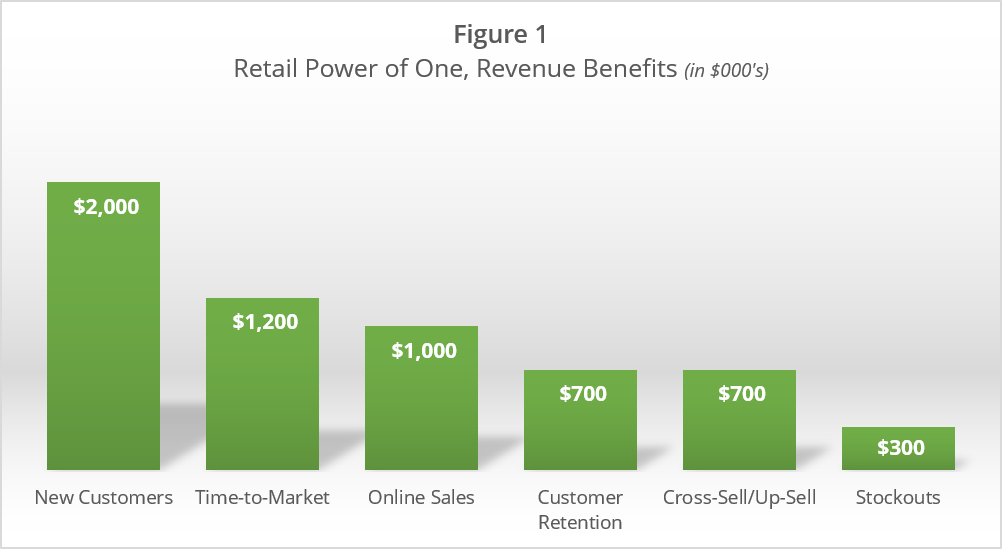

Let’s first explore revenue benefits using Retail as an example. Retailers who collaborate with their key manufacturers, for example, by sharing customer demand from their point of sale experience, will realize business benefits such as better management of securing production capacity, improved merchandise availability, faster time to bring seasonal fashion items to the market, and reduced logistics expenses.

Figure 1 shows financial benefits from a one percent improvement (what we like to call the Power of One) in a few of the revenue-related key performance indicators potentially improved by supply chain collaboration; for example, by enhancing the customer experience. The total revenue benefit is almost $6 million per $1 billion in revenue, and adds close to $2 million in gross profit for the average retailer. This would be music to the ears of a Chief Merchandising Officer, Marketing Officers, and CFO. These results are for illustrative purposes only, but they help to demonstrate why supply chain collaboration is a strategic imperative deserving of boardroom consideration.

Scaled to retailer with $1 billion in revenue

Now let’s explore some examples of supply chain collaboration’s operating expense and asset benefits.

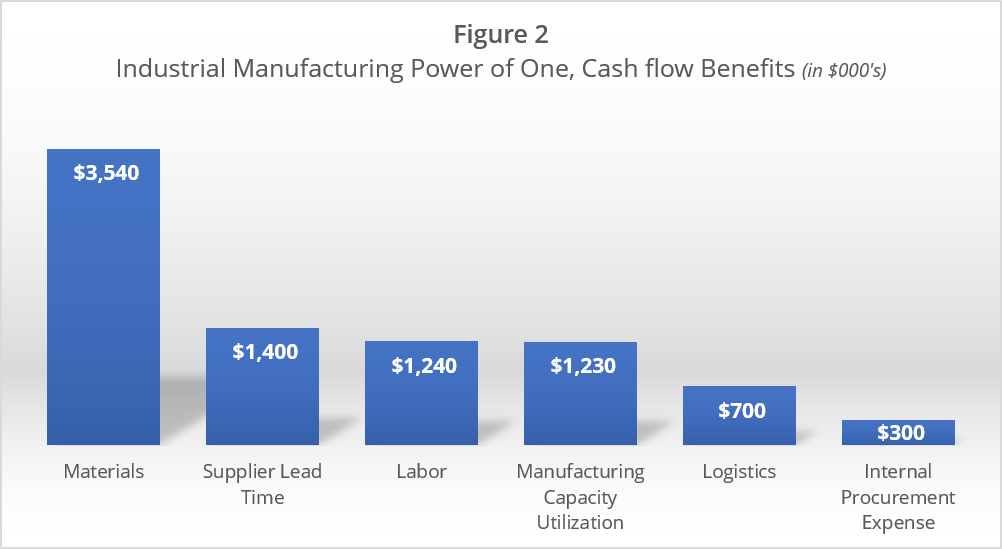

If your business is in the upper stream of the supply chain network, applying supply chain collaboration between procurement and supply chain management can reduce the risk for key components to feed a smooth flow of your manufacturing production needs. Collaborating with key suppliers improves activities like demand planning, inventory planning, lead-time optimization, and product lifecycle management. Shortening the time it takes to complete these activities improves efficiency. Improving resource usage improves effectiveness. All of this enhances agility, profitability, asset utilization, and ultimately, cash flow and overall financial performance.

Figure 2 shows the cash flow benefits from a 1% improvement in operating expense and asset-related operational KPIs improved by supply chain collaboration for an industrial manufacturer. These areas include operating expenses like materials and logistics costs, and assets such as inventory and production assets. The total improvement is over $8 million, which would increase profitability by 80 basis points per $1 billion in revenue. You can bet this would catch the attention of the CFO!

Scaled to industrial manufacturer with $1 billion in revenue

How to get there from here? Supply chain collaboration requires integration of processes between and across internal and external stakeholders. It’s important to know what your key strengths are, what areas need improvement, and for those areas needing improvement – are they best addressed using internal resources or relying on partners? Additionally, the challenges of internal integration cannot be underestimated. Each stakeholder is often aligned with common goals like growing the top and bottom lines. But to help achieve these goals, internal stakeholders may have conflicting initiatives and dashboards. If internal integration between departments is not well established, it presents a greater challenge to achieve successful supply chain collaborations with external stakeholders. The supply chain executive who leads the supply chain collaboration needs to be placed at an upper level in the organization. This way they can lead, support, and remove roadblocks along the way.

Next steps: identify those areas of the business potentially improved with better supply chain collaboration. What are the operational KPIs related to these areas? What are the revenue and cash flow benefits from a 1% improvement to these KPIs?

Good luck!